PRODUCT PARAMETERS

Description

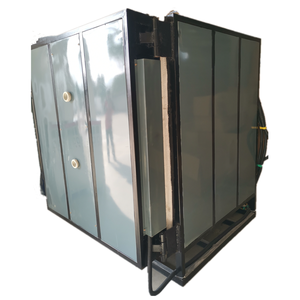

Introduction of New Typesmall rotary tunnel kiln used kiln for red brick soil brick

A rotary kiln is a kind of industrial equipment used for material heating and processing, which is widely used in cement, metallurgy, chemical industry, etc. New Typesmall rotary tunnel kiln used kiln for red brick soil brick refers to various parts and components which are necessary for maintaining and repairing the normal operation of the rotary kiln, such as cylinder, baffle wheel, pallet, sealing device and so on.

Features and advantages of New Typesmall rotary tunnel kiln used kiln for red brick soil brick

High-temperature resistance: Due to the extremely high temperature of the working environment of the rotary kiln, the spare parts are usually made of refractory materials or special alloys to ensure that they can work stably under high temperatures.

High abrasion resistance: Long time material friction and chemical erosion require spare parts to have excellent abrasion resistance to prolong service life.

High structural strength: in order to withstand heavy loads and the pressure of continuous operation, the design of spare parts will place special emphasis on structural strength and reliability.

Easy to install and maintain: Considering the need for frequent replacement, many spare parts are designed to be simpler and easier for quick installation and maintenance.

Strong adaptability: different industries have different needs for rotary kilns, so spare parts need to have good versatility and adaptability to meet diverse application conditions.

(New Typesmall rotary tunnel kiln used kiln for red brick soil brick)

Specifications of New Typesmall rotary tunnel kiln used kiln for red brick soil brick

The New Typesmall rotary tunnel kiln is designed for producing red bricks and soil bricks. It works for small to medium factories. The kiln has a compact design. It saves space. The inner diameter is 2.5 meters. The length is 40 meters. The rotating system ensures even heat distribution. Bricks move smoothly through the tunnel. This reduces cracks and defects. The kiln operates between 800°C and 1200°C. Temperature control is precise. Adjustments are easy. A digital panel shows real-time data. Workers monitor conditions without guesswork. The kiln uses coal, gas, or biomass as fuel. Factories choose based on cost and availability. Fuel efficiency is high. Heat loss is minimal. Insulation layers are thick. Refractory materials last long. Maintenance costs stay low. Production capacity reaches 15,000 to 20,000 bricks daily. The process is continuous. Loading and unloading zones work nonstop. Automation cuts labor needs. Conveyor belts transport raw materials. Robots stack finished bricks. Safety features include emergency cooling and pressure release valves. Alarms trigger for overheating or blockages. The structure is steel-framed. It resists corrosion. Installation is simple. No deep foundation is required. Local technicians handle setup. Training is provided. The kiln suits clay, shale, or mixed soil. Moisture content in raw materials can vary. Drying chambers remove excess water before firing. Bricks come out uniform in color and strength. Testing meets industry standards. Export packaging protects parts during shipping. Custom modifications are available. Clients request size or fuel adjustments. Spare parts are easy to source. Technical support responds quickly. This kiln balances performance and affordability. Small businesses upgrade without high costs. It fits rural or urban workshops. Red bricks and soil bricks sell well in construction markets.

(New Typesmall rotary tunnel kiln used kiln for red brick soil brick)

Applications of New Typesmall rotary tunnel kiln used kiln for red brick soil brick

The new small rotary tunnel kiln works for making red bricks and soil bricks. It handles clay and soil materials well. This kiln fits small factories or projects needing steady brick output. It uses less energy than old kilns. This cuts fuel costs. Factories save money. The kiln heats bricks evenly. Bricks come out strong. Fewer break during firing. Builders use these bricks for houses, walls, roads. The kiln suits rural and urban construction. It makes bricks fast. Small businesses get more products quickly. Workers find it easy to operate. Automation reduces manual labor. Owners spend less on hiring. The kiln adjusts to different soil types. It works with local materials. Factories avoid buying expensive clay. Brick quality stays consistent. Projects face fewer delays. Farmers use soil bricks for barns, storage sheds. The kiln’s small size saves space. Factories install it without major changes. Maintenance stays simple. Parts last long. Downtime drops. Repair costs stay low. The kiln runs on coal, gas, or biomass. Factories pick fuels based on price. Rural areas with limited resources still use it. Emissions stay low. It meets environmental rules. Governments support cleaner kilns. Factories avoid fines. Buyers prefer eco-friendly bricks. The kiln’s design prevents heat loss. Temperatures stay steady. Fuel use drops further. Bricks cool faster. Production cycles shorten. Factories make more batches daily. Demand grows in developing regions. Housing projects need cheap, durable bricks. The kiln helps meet this need. Urban developers use these bricks for affordable homes. Roads and pavements last longer with high-quality bricks. The kiln’s reliability keeps projects on schedule. Owners expand production without big investments. It adapts to market changes. New businesses enter the brick industry easily. Training workers takes little time. The kiln’s low risk attracts small investors. Brick prices stay competitive. Construction costs drop for buyers. The kiln supports local job creation. Communities benefit from affordable housing and infrastructure. Its role in sustainable building grows as cities expand.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of New Typesmall rotary tunnel kiln used kiln for red brick soil brick

What is a rotary tunnel kiln used for red brick production? It heats raw materials like clay or soil to high temperatures. The process turns them into solid bricks. This kiln type suits large-scale projects. It ensures consistent quality in brick manufacturing.

How does the rotary tunnel kiln work? Raw bricks move through a rotating heated chamber. Heat zones dry, bake, and cool bricks step by step. The rotation spreads heat evenly. This reduces cracks or defects. The system uses less energy compared to older kilns.

What materials can this kiln handle? It works with red clay, soil, or mixed materials. The design adjusts to different moisture levels. Some models handle additives like ash or sand. The kiln avoids strict material requirements. This flexibility lowers production costs.

What makes this kiln better than traditional ones? It heats bricks uniformly due to steady rotation. Temperature control is precise. This cuts fuel waste. Automation reduces manual labor. Firing time is shorter. Output increases without quality loss.

How long does the kiln last with regular use? Proper maintenance extends its lifespan. Key parts like seals or burners need checks every 3–6 months. Replacing worn parts early prevents breakdowns. Average lifespan is 8–12 years. Harsh conditions or poor care may shorten this.

(New Typesmall rotary tunnel kiln used kiln for red brick soil brick)

REQUEST A QUOTE

RELATED PRODUCTS

2024 OEM Rotary Kiln Spare parts trunnion roller Trunnion Wheels

Rotary Kiln 5 M3 Zinc Oxide Waelz Small Rotary Kiln To Make Cement

Clay Aggregate Production Line Ceramic Pelletizer LECA Rotary Kiln Factory Direct

Cement Rotary Kiln Seal Rotary Kiln Barrel Parts

Wide Adaptability High Strength Double Swirl Rotary Kiln Burner Low Cost Double Swirl Rotary Kiln Burner