PRODUCT PARAMETERS

Description

Introduction of Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel

A rotary kiln is a kind of industrial equipment used for material heating and processing, which is widely used in cement, metallurgy, chemical industry, etc. Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel refers to various parts and components which are necessary for maintaining and repairing the normal operation of the rotary kiln, such as cylinder, baffle wheel, pallet, sealing device and so on.

Features and advantages of Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel

High-temperature resistance: Due to the extremely high temperature of the working environment of the rotary kiln, the spare parts are usually made of refractory materials or special alloys to ensure that they can work stably under high temperatures.

High abrasion resistance: Long time material friction and chemical erosion require spare parts to have excellent abrasion resistance to prolong service life.

High structural strength: in order to withstand heavy loads and the pressure of continuous operation, the design of spare parts will place special emphasis on structural strength and reliability.

Easy to install and maintain: Considering the need for frequent replacement, many spare parts are designed to be simpler and easier for quick installation and maintenance.

Strong adaptability: different industries have different needs for rotary kilns, so spare parts need to have good versatility and adaptability to meet diverse application conditions.

(Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel)

Specifications of Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel

The Large Wheel Large Diameter Spur Gear is a high-quality, precision-engineered component designed for heavy-duty industrial applications, particularly in rotary kilns and other large-scale machinery. Manufactured using advanced CNC machining techniques, this spur gear ensures exceptional accuracy, durability, and performance under demanding conditions. The gear is crafted from premium-grade materials, such as high-strength alloy steel or carbon steel, which provide superior resistance to wear, corrosion, and high temperatures, making it ideal for use in harsh environments.

The large diameter of this spur gear allows it to handle significant torque and rotational forces, ensuring smooth and efficient power transmission in rotary kilns and similar equipment. Its precise tooth profile, achieved through CNC machining, guarantees minimal backlash and optimal meshing with mating gears, reducing noise and vibration during operation. This results in enhanced operational efficiency and extended service life for the entire system.

The gear’s robust construction and high load-bearing capacity make it suitable for applications requiring continuous operation and heavy loads, such as cement production, mining, and metallurgical processes. It is available in a range of sizes and specifications to meet the unique requirements of different industries and machinery configurations. Customization options include variations in diameter, tooth count, pitch, and material composition, ensuring compatibility with a wide array of equipment.

Surface treatments, such as heat treatment, hardening, or coating, can be applied to further enhance the gear’s performance and longevity. These treatments improve hardness, reduce friction, and protect against environmental factors, ensuring reliable operation even in extreme conditions. The Large Wheel Large Diameter Spur Gear is a critical component for industries that demand precision, reliability, and durability in their machinery, making it an indispensable part of modern industrial operations.

(Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel)

Applications of Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel

The large wheel, large diameter spur gear, manufactured through high-quality CNC machining, is a critical component in various industrial applications, particularly in rotary kilns and heavy machinery. These gears are designed to handle extreme loads, high torque, and continuous operation, making them indispensable in industries such as cement production, mining, metallurgy, and chemical processing. The precision and durability of CNC-machined spur gears ensure smooth and efficient power transmission, reducing downtime and maintenance costs.

In rotary kilns, the large diameter spur gear plays a pivotal role in the rotation of the kiln drum, which is essential for processes like calcination, sintering, and thermal treatment of materials. The high-quality machining ensures that the gear meshes perfectly with the pinion, providing consistent and reliable performance even under high temperatures and harsh conditions. The robust construction of these gears, often made from high-grade alloy steels, ensures resistance to wear, deformation, and fatigue, extending the lifespan of the equipment.

The CNC machining process allows for tight tolerances and superior surface finishes, which are crucial for the smooth operation of large wheels and gears. This precision minimizes vibrations and noise, enhancing the overall efficiency of the machinery. Additionally, the ability to customize these gears to specific requirements makes them suitable for a wide range of applications, from heavy-duty industrial machinery to specialized equipment in the energy and construction sectors.

Overall, the large wheel, large diameter spur gear, produced through high-quality CNC machining, is a testament to advanced engineering and manufacturing excellence. Its applications in rotary kilns and other heavy industries underscore its importance in ensuring operational reliability, efficiency, and longevity, making it a vital component in modern industrial processes.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel

When it comes to large wheel, large diameter spur gears, and high-quality CNC machining for rotary kiln big wheels, there are several common questions that arise. Here are five frequently asked questions to help you better understand these components and their applications:

1. **What is a large diameter spur gear, and where is it used?**

A large diameter spur gear is a toothed wheel designed to transmit power and motion between parallel shafts. These gears are commonly used in heavy-duty industrial applications, such as rotary kilns, cement plants, and mining equipment, where high torque and precision are required. Their large size ensures durability and efficient power transfer in demanding environments.

2. **Why is CNC machining important for these gears?**

CNC (Computer Numerical Control) machining ensures high precision and consistency in the manufacturing of large diameter spur gears. This process allows for tight tolerances, smooth finishes, and accurate tooth profiles, which are critical for reducing wear, minimizing noise, and ensuring long-term performance in rotary kiln applications.

3. **What materials are used to make these gears?**

Large diameter spur gears are typically made from high-strength materials such as alloy steel, carbon steel, or cast iron. These materials are chosen for their durability, resistance to wear, and ability to withstand heavy loads and harsh operating conditions. Heat treatment processes like carburizing or quenching may also be applied to enhance hardness and longevity.

4. **How do I maintain a large diameter spur gear in a rotary kiln?**

Regular maintenance is essential to ensure the longevity of large diameter spur gears. This includes routine inspections for wear, proper lubrication to reduce friction, and alignment checks to prevent uneven load distribution. Addressing issues like tooth damage or misalignment early can prevent costly downtime and repairs.

5. **Can custom gears be manufactured for specific applications?**

Yes, many manufacturers offer custom CNC machining services to produce large diameter spur gears tailored to specific requirements. Whether you need unique dimensions, specialized materials, or specific tooth profiles, custom gears can be designed and manufactured to meet the exact needs of your rotary kiln or other industrial machinery.

In summary, large diameter spur gears are critical components in heavy machinery, and their quality, precision, and maintenance play a vital role in ensuring optimal performance. CNC machining and high-quality materials make these gears reliable solutions for demanding industrial applications.

(Large Wheel Large Diameter Spur Gear High Quality Cnc Machining Rotary Kiln Big Wheel)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Large Cement Plant Rotary Kiln Parts Large Diameter Gear Ring

Lime Powder Rotary Drum Kiln Furnace Rotary Limestone Kiln Cement Rotary Kiln for

Cement Rotary Kiln Seal Rotary Kiln Barrel Parts

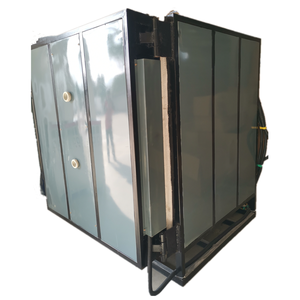

Metal Metallurgy Machinery Top ing For Producing Parts Advanced Machines High Quality Arc Metal Industrial Sintering Furnace

Laboratory Kiln 1100 1200 1400 1500 1600 1700 1800 Celsius Degree Electric Ceramic Box Melting Oven Vacuum Muffle Furnace