PRODUCT PARAMETERS

Description

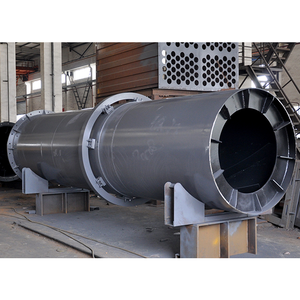

Introduction to Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer

Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer)

Specifications of Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer

The Hot Air Manure Dryer Gypsum Powder Clothes Dryer Equipment Fertilizer Drying Maker Rotary Drum Clothes dryer is created for drying natural manure, plaster powder, plant food, and similar materials. This equipment uses high-temperature air flow to eliminate moisture successfully. It works for small ranches and big industrial plants. The clothes dryer handles materials with high humidity, lowering dampness content to below 10%.

The drum is made of durable stainless steel. This protects against rust and prolongs the maker’s life-span. The internal drum has lifting plates to turn materials evenly. Warmth circulation remains regular during drying out. The equipment supports constant operation. It saves time and labor compared to standard drying approaches.

Home heating sources include coal, gas, biomass, or electrical energy. Users choose based upon availability and cost. The drying temperature level readjusts between 80 ° C and 600 ° C. This fits various material demands. Thermal sensing units keep an eye on warm levels. They protect against overheating and material damages.

The maker’s ability varies from 500kg to 20 bunches per hour. Drum diameters vary from 1.2 meters to 3 meters. Lengths cover 6 meters to 25 meters. Power intake depends on dimension and tons. Criterion models use 15kW to 75kW electric motors. Drying out cycles take 20 to 60 minutes. This depends on material type and initial dampness degrees.

The framework consists of a feeding belt, turning drum, warm generator, cyclone separator, and discharge system. Warm air enters the drum through a covered pipeline. Damp products combine with warm air inside the drum. Moisture vaporizes promptly. Dry products exit via the discharge port. Dirt is filtered through the cyclone separator. This lowers pollution.

Benefits consist of low energy usage, high efficiency, and straightforward upkeep. The machine’s insulation layer reduces heat loss. Automatic regulates readjust rate and temperature. This ensures stable efficiency. Wear-resistant products lower component substitute regularity.

The dryer refines animals manure, poultry waste, garden compost, gypsum, sludge, and chemical fertilizers. It meets farming and industrial standards. Security features include overload protection and emergency situation quits. Operators get standard training for setup and troubleshooting. Routine cleaning avoids blockages. Lubrication maintains parts running smoothly.

(Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer)

Applications of Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer

Hot Air Manure Dryer Gypsum Powder Dryer Device Fertilizer Drying Device Rotary Drum Clothes dryer serve vital roles across markets. These makers deal with drying tasks effectively. Hot Air Manure Clothes dryer processes natural waste like pet manure. It minimizes moisture swiftly. Farmers use dried manure as natural plant food. This approach cuts waste. It enhances soil top quality. The equipment runs at high temperatures. It makes sure secure drying out. Damaging virus get eliminated. The procedure is environment-friendly.

Plaster Powder Dryer Device concentrates on building and construction products. Plaster needs drying out before usage in plaster or cement. The machine heats up gypsum equally. Wetness levels drop below 1%. This improves product toughness. Contractors count on consistent results. The system works quick. It saves power. Upkeep prices remain low. Manufacturing facilities favor it for mass handling.

Fertilizer Drying Machine targets agricultural markets. Wet fertilizer pellets clump together. This machine dries them rapidly. Consistent drying avoids nutrition loss. Farmers obtain free-flowing granules. Storage comes to be simpler. Crop returns improve. The style handles big batches. It adapts to various fertilizer types. Warmth settings readjust for delicate materials.

Rotating Drum Clothes dryer suits multiple industries. Its turning cylinder mixes materials as they dry. Applications include minerals chemicals and biomass. The big ability satisfies industrial needs. Hot air flows with the drum. Wetness evaporates continuously. Operators control drying out rate. The equipment functions nonstop. Toughness guarantees lasting usage. It deals with unpleasant or sticky substances.

These equipments share core benefits. They lower manual labor. Energy effectiveness decreases expenses. Outcome quality stays high. Each device fits particular requirements. Hot Air Manure Clothes dryer supports sustainable farming. Gypsum Powder Clothes dryer aids building jobs. Fertilizer Drying Maker enhances crop manufacturing. Rotary Drum Dryer serves diverse industrial processes. Individuals focus on dependability. Routine maintenance makes sure peak performance. Appropriate operation prolongs device lifespan.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer

Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer FAQs

What does this dryer do? The machine removes moisture from materials like manure, gypsum powder, or fertilizer. Hot air flows through a rotating drum. Wet materials tumble inside. Heat evaporates water. Dry material exits the drum. The process is continuous.

What materials can it dry? It handles organic waste, animal manure, gypsum powder, sludge, or fertilizer. Particle size matters. Materials should be smaller than 3cm. Sticky or overly wet substances might need pre-treatment. The machine works best with free-flowing granules or powders.

How long does drying take? Drying time depends on moisture content, material type, and temperature. High moisture takes longer. Typical cycles range 20-60 minutes. Adjusting airflow or heat reduces time. Monitor output moisture levels.

Is the machine safe? Safety features prevent accidents. The drum has temperature sensors. Overheating triggers automatic shutdown. Electrical parts have waterproof covers. Sturdy frames prevent tipping. Follow operating guidelines. Regular checks ensure safety.

How to maintain it? Clean the drum after each batch. Check heating coils monthly. Lubricate bearings every two weeks. Inspect belts for wear. Replace damaged parts quickly. Store the machine in dry areas when unused. Maintenance keeps it efficient.

Energy efficiency matters. The dryer uses recycled heat systems. Insulated drums reduce heat loss. Adjustable fans control airflow. Proper settings lower fuel or electricity use. Efficient drying cuts operating costs.

(Hot Air Manure Dryer Gypsum Powder Dryer Machine Fertilizer Drying Machine Rotary Drum Dryer)

REQUEST A QUOTE

RELATED PRODUCTS

Customized rotary dryer 7.8 meter cube industrial dryer rotary dryer with automatic control system

Small Rotary Drum Dryer Machine for Chemical Industry Powders Economical Rotary Drying Equipment for Manufacturing Plant

Professional industrial instant Baby Food Flake Double Drum Dryer Starch dryer active dry yeast rotary drum scraper dryer

New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

High Quality Factory Dryer Parts 303373K Drum Roller Wheel Support Kit