PRODUCT PARAMETERS

Description

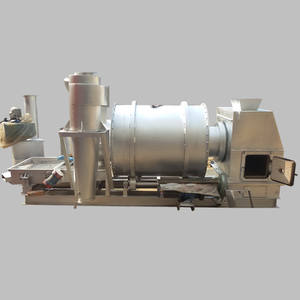

Introduction to Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer

Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer)

Specifications of Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer

The Cheaper Granulating Euro Dryer Device Plastic Recycling Blower and Dryer is an economical solution created for small to medium-scale plastic reusing procedures. This integrated system incorporates granulation, drying, and blower functions to simplify the recycling process while minimizing power intake and operational expenses. The granulating system features a robust stainless steel reducing chamber with hardened blades with the ability of processing approximately 200-300 kg of plastic waste per hour, depending upon material type (e.g., PET DOG, HDPE, LDPE). It includes a 7.5-10 kW electric motor for efficient shredding, with adjustable mesh displays (3-12 mm) to manage granule size. The Euro clothes dryer component makes use of a centrifugal drying out system with a 3-5 kW high-speed blower electric motor, creating airflow rates of 1500-2000 m ³/ h to remove surface area dampness from flakes. The drying chamber is constructed from corrosion-resistant galvanized steel, with a capacity of 50-100 liters and a dwell time of 15-30 minutes for regular moisture decrease. The system integrates a 6-9 kW home heating device for optional thermal drying out, getting to temperatures up to 120 ° C for hygroscopic materials. Sound levels are kept below 75 dB for work environment conformity. The blower system includes a cyclone separator with 95%+ efficiency to lessen material loss and a HEPA filter for dirt control. Electric parts are IP55-rated for moisture resistance, and the machine operates 380V/50Hz three-phase power. Small dimensions (approx. 2.5 m x 1.2 m x 2m) make it appropriate for minimal spaces. Safety attributes consist of overload protection, emergency situation quit switches, and thermal sensors. While made as a spending plan choice, it maintains sturdiness with 2-3 mm steel framework building and construction and requires marginal maintenance– recommended lubrication periods of 500 operating hours. The system attains recurring dampness material below 1% for a lot of plastics, making certain outcome top quality for extrusion or molding processes. Suitable for start-ups or centers prioritizing cost-efficiency without compromising core performance.

(Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer)

Applications of Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer

The Cheaper Granulating Euro Dryer Device, combined with a Plastic Recycling Blower and Dryer system, is a flexible remedy made to improve plastic recycling procedures across sectors. This incorporated configuration efficiently manages wetness removal, granulation, and drying, making it excellent for transforming post-consumer or post-industrial plastic waste into multiple-use resources. Its cost-efficient design ensures access for small to medium-sized reusing procedures while maintaining high efficiency.

Key applications include processing plastic flakes from bottles, containers, and packaging materials. The blower system accelerates airflow to eliminate surface area dampness, while the Euro clothes dryer utilizes regulated heat to remove residual humidity, making certain optimal material quality prior to granulation. This is crucial for creating constant plastic pellets utilized in producing new products like textiles, automotive components, and building materials.

The system masters recycling agricultural movies, inflexible plastics, and industrial scraps, consisting of PP, PE, FAMILY PET, and HDPE. Its granulating device shreds plastic right into consistent granules, which are then dried out to avoid destruction throughout storage space or reprocessing. This is specifically beneficial for recycling facilities aiming to meet stringent high quality criteria for recycled plastics in food-grade or clinical applications.

Another application is in taking care of mixed or infected plastics. The blower separates lightweight contaminants, while the clothes dryer guarantees comprehensive wetness evaporation, lowering the threat of microbial development or product clumping. This makes the system appropriate for recycling post-consumer waste from land fills or marine settings, contributing to round economic climate goals.

The equipment’s energy-efficient style minimizes operational prices, and its small impact suits centers with restricted space. By reducing moisture-related defects in recycled pellets, it enhances the durability and visual charm of final product. Industries like product packaging, auto, and electronics take advantage of high-purity recycled plastics created utilizing this system.

On the whole, the Cheaper Granulating Euro Clothes Dryer Machine and Plastic Recycling Blower combo offers a budget-friendly, scalable solution for changing plastic waste right into important sources. It supports sustainability efforts, reduces dependence on virgin plastics, and encourages businesses to fulfill environmental laws while maintaining profitability.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer

What is the primary function of the Cheaper Granulating Euro Dryer Machine in plastic recycling? The machine combines granulating, drying, and blower systems to process plastic waste. It shreds plastic into uniform granules, removes moisture via a high-temperature Euro dryer, and uses a blower to circulate hot air for efficient drying. This integrated process prepares recycled plastic for reuse in manufacturing by ensuring clean, dry, and consistent material output.

Why choose a cheaper granulating and drying machine over traditional models? This model is cost-effective without compromising core functionality. It uses simplified, durable components that reduce upfront costs while maintaining energy efficiency and reliability. Ideal for small to mid-sized recyclers, it offers essential features like adjustable temperature controls, robust blower airflow, and easy maintenance—making it accessible for businesses aiming to scale operations affordably.

How does the blower system enhance drying efficiency? The blower ensures consistent airflow across wet plastic granules, accelerating evaporation. Its design minimizes heat loss, allowing the Euro dryer to maintain optimal temperatures. This reduces drying time by up to 30% compared to passive systems, lowering energy consumption and operational costs while preventing overheating or uneven drying.

What maintenance does the machine require? Regular cleaning of filters and ducts prevents clogging from plastic residues. Lubricate moving parts monthly, inspect heating elements for wear, and check the blower motor for dust buildup. The granulator blades may need sharpening or replacement after prolonged use. These steps ensure longevity and consistent performance without costly repairs.

Can it handle different types of plastics? Yes. The machine processes common plastics like PET, HDPE, LDPE, and PP in flakes or pellets. Adjustable temperature settings (40°C–120°C) accommodate varying moisture levels and melting points. However, overly sticky or contaminated materials may require pre-treatment to avoid clogging. Always consult the manual for material-specific guidelines to optimize output quality.

(Cheaper Granulating Euro dryer Machine Plastic Recycling Blower And dryer)

REQUEST A QUOTE

RELATED PRODUCTS

Automatic agricultural grain dryer dregs soybean meal rotary drum dryer

Single rotary drum dryer for biomass rice husk sa and secador rotary dryer pellet for phosphates and sand dryer spare parts buck

Professional industrial instant Baby Food Flake Double Drum Dryer Starch dryer active dry yeast rotary drum scraper dryer

Rotary roller drum dryer machine rotary scraper drum dryer food flake

rotary drum dryer/ series double cone