PRODUCT PARAMETERS

Description

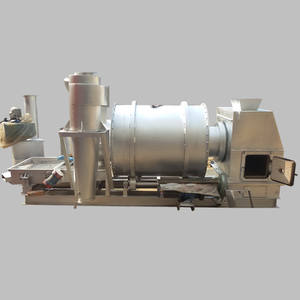

Introduction to a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts

a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts)

Specifications of a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts

The 10tph coal slime cassava rotary dryer is a reliable and efficient machine designed to handle the tough job of drying lignite or coal slime at maximum capacity of 10tph. This machine features a high-pressure impeller that drives water through the dryer’s cavities, allowing for faster drying times.

The dryer’s capacity can be adjusted according to your specific needs, making it ideal for large-scale applications such as mining or power generation. The dryer also has a built-in safety system that ensures proper ventilation and prevents overheating.

Spare parts are available for this machine to ensure that you can keep the dryer running smoothly even if one part fails. These spare parts include bearings, gaskets, motors, and control panels among others.

In addition to its high efficiency and durable construction, the 10tph coal slime cassava rotary dryer is also easy to maintain and operate. The machine is equipped with simple controls that allow operators to adjust settings and monitor performance in real-time.

Overall, the 10tph coal slime cassava rotary dryer is an excellent choice for those looking for a reliable and efficient solution for dry-lining coal and lignite. With its extensive range of spare parts and user-friendly controls, this machine offers top-notch performance and durability.

(a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts)

Applications of a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts

A 10tph rotary drum dryer is a highly effective machine used in the production of coal slime and cassava products. The dryer uses a drum configuration with three turns, providing efficient heat transfer to help convert moisture into steam for drying.

One of the key benefits of using a rotary drum dryer is that it can handle high temperatures, making it suitable for use in industries such as mining, construction, and agriculture. The dryer also has good airflow control, ensuring that air does not get blocked or stagnate, which helps to improve the efficiency of the process.

The dryer is also equipped with a series of spare parts, including motors, control panels, filters, and drying chambers. These spare parts ensure that the dryer can be easily repaired or replaced when necessary, reducing downtime and minimizing maintenance costs.

In addition to its technical capabilities, the 10tph rotary drum dryer is also easy to operate and maintain. The control panel provides real-time monitoring of temperature, humidity, and other important parameters, while the spare parts ensure that the dryer can operate reliably at all times.

Overall, the 10tph rotary drum dryer is an excellent choice for those looking for a reliable and efficient way to produce coal slime and cassava products. Its high temperature capability, good airflow control, and availability of spare parts make it an ideal solution for a wide range of applications.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts

1. What is a rotary drum dryer?

A rotary drum dryer is a type of dryer used to dry coal slime and cassava by using heat from hot water. The dryer has rotating drums that rotate at different speeds, causing the moisture in the materials to evaporate.

2. How does the rotary drum dryer work?

The rotary drum dryer works by passing hot water through the dryer’s rotating drums, which causes the materials to be dried. The heating allows the materials to evaporate moisture, leaving them dry and ready for use.

3. Are there any safety precautions to take when operating a rotary drum dryer?

Yes, there are several safety precautions to take when operating a rotary drum dryer. These include wearing appropriate personal protective equipment (PPE), such as gloves and goggles, as well as following the manufacturer’s instructions carefully.

4. Is it necessary to replace the spare parts of the dryer?

No, it is not necessary to replace the spare parts of the dryer if they are functioning properly. However, if the dryer breaks down or malfunctions, replacing the parts can help prevent further damage and extend its lifespan.

5. How long will it take to dry a sample of coal slime or cassava using a rotary drum dryer?

The drying time for a sample of coal slime or cassava using a rotary drum dryer will depend on several factors, including the temperature of the water and the size of the material being dried. Generally speaking, it should take anywhere from 30 minutes to several hours to fully dry a sample using a rotary drum dryer.

(a 10tph rotary drum dryer Coal Slime Cassava Rotary Dryer With Spare Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Euro Standard Economical Plastic Hopper Dryer Machine For

Small Rotary Drum Dryer Machine for Chemical Industry Powders Economical Rotary Drying Equipment for Manufacturing Plant

sewage waste water filter rotating rotary drum thickener sludge belt dryer machine s

Series Vacuum Harrow Dryer Farm Food Processing Drying machine with Core Motor Component

Advanced Technology Drying Equipment Rotary Drum Dryer