PRODUCT PARAMETERS

Description

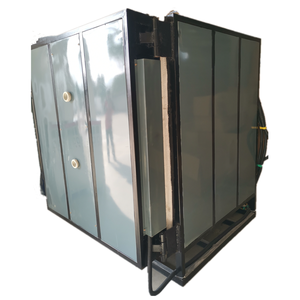

Introduction of Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module

Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module refers to components that are specially designed and manufactured to replace or repair heavy machinery and equipment according to specific customer needs and specifications. These spare parts can be of any non-standard size, shape or function and are designed to meet the unique requirements of a specific application.

Advantages and features of Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module

Precise fit: Precisely matched spare parts for specific models or aging heavy machinery to ensure proper operation.

Extended life: High-quality materials and excellent artistry help to extend the life of machinery and equipment.

Cost-effective: Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module can significantly reduce costs compared to purchasing a completely new machine.

Rapid Response: The ability to respond quickly to customer needs shortens lead times and reduces downtime.

Innovative design: Using the latest technology and materials science to provide customers with optimized design solutions that improve efficiency and performance.

(Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module)

Specification of Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module

Steel commercial extra components for heavy industry devices are engineered to deliver exceptional resilience, accuracy, and performance popular atmospheres. These parts are crafted from high-grade steel alloys, such as ASTM A36, A572, or stainless steel versions, guaranteeing resistance to wear, deterioration, and severe temperatures. Common specs consist of tensile staminas varying from 400 MPa to 850 MPa, with solidity levels maximized for heavy-load applications. Components are machined to tight tolerances (ISO 2768-f or higher) to guarantee smooth assimilation with existing machinery systems.

The modular design of these systems permits easy assembly, replacement, and scalability, reducing downtime in commercial procedures. Trick components include equipments, shafts, bearings, screws, and custom-fabricated braces, all developed to satisfy ISO 9001 and ASME standards. Surface therapies like hot-dip galvanizing, powder coating, or nitride solidifying boost durability, also in abrasive or chemically hostile environments. Load-bearing abilities range from 5 bunches to 500 lots, depending upon the application, with exhaustion resistance checked over 10 ^ 6 cycles.

Interchangeability is a core function, with standardized threading (UNC/UNF), bore sizes, and flange dimensions to make sure compatibility across worldwide equipment systems. Advanced heat therapy processes, such as quenching and tempering, refine grain structures for ideal strength-to-weight proportions. Parts are checked for dimensional precision utilizing CMM (Coordinate Determining Maker) and ultrasonic imperfection detection to remove issues.

The component system sustains assimilation with automation technologies, including IoT-enabled sensing units for real-time tracking of anxiety, temperature level, and resonance. Personalized layouts deal with fields like mining, construction, energy, and manufacturing, with CAD/CAM prototyping offered for bespoke services. Ecological conformity sticks to RoHS and REACH instructions, emphasizing recyclability and reduced carbon impact.

These steel extra components are optimal for conveyor systems, crushers, presses, and hydraulic equipment, providing a life expectancy surpassing 15 years under routine upkeep. Packaging consists of anti-rust VCI coverings and shock-resistant crating for global logistics. Backed by licensed metallurgical reports and 24/7 technical assistance, this system makes certain functional integrity, expense performance, and security in heavy industrial applications.

(Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module)

Applications of Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module

Steel commercial spare parts are essential elements in heavy market devices, developed to deliver longevity, toughness, and reliability sought after environments. These components develop the foundation of modular systems utilized across markets like production, construction, mining, power, and transport. Their applications make sure smooth procedures, decreased downtime, and boosted efficiency. In producing plants, steel spare parts such as equipments, shafts, and hydraulic parts are indispensable to machinery like presses, conveyors, and assembly lines. They endure high tension, repetitive activity, and severe temperatures, making certain lasting capability. In construction, hefty equipment like cranes, excavators, and excavators rely upon steel bolts, structures, and use plates to take care of hefty loads and abrasive conditions. Modular systems allow fast substitute of used components, decreasing job hold-ups. The mining sector take advantage of steel elements in exploration rigs, crushers, and conveyor belts, where resistance to corrosion and effect is vital. Modular styles enable quick upkeep in remote areas, improving functional effectiveness. Energy fields, including oil, gas, and renewables, make use of steel valves, pipelines, and wind turbine parts to take care of high-pressure liquids and mechanical anxiety. These systems support modular upgrades, adjusting to progressing energy demands. Transport framework, such as railways and ports, depends on steel combinings, bearings, and structural supports to guarantee safe, dependable activity of goods. Modularity simplifies fixings and scalability, lining up with vibrant logistics needs. Steel’s versatility allows modification for particular applications, while standard components reduce inventory costs. The product’s recyclability straightens with sustainability goals, reducing environmental impact. By integrating steel commercial spare parts into modular systems, sectors attain expense savings via extensive equipment lifespans, reduced upkeep, and minimized downtime. Their effectiveness and compatibility with contemporary automation technologies additionally boost precision and operational control. Ultimately, steel-based modular systems are a keystone of commercial progression, allowing strength, flexibility, and performance in an ever-evolving worldwide market.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module

What are steel industrial spare parts heavy industry equipment modules? Steel industrial spare parts heavy industry equipment modules are pre-engineered, customizable systems designed to replace or upgrade critical components in heavy machinery used in industries like steel production, mining, and construction. These modules include gears, bearings, hydraulic systems, conveyor parts, and structural assemblies, built to withstand extreme conditions such as high temperatures, heavy loads, and corrosive environments. They ensure seamless integration with existing equipment to minimize downtime and enhance operational efficiency.

Why choose this system over traditional spare parts? This modular system offers superior durability, precision engineering, and faster installation compared to traditional spare parts. Modules are pre-tested for performance and compatibility, reducing the risk of malfunctions. Customization options allow adaptation to specific machinery requirements, while standardized designs simplify maintenance. The modular approach also extends equipment lifespan by enabling targeted repairs instead of full replacements, saving time and costs.

How often should modules be inspected or replaced? Inspection intervals depend on operational intensity and environmental factors. Generally, modules should undergo routine checks every 3–6 months, with replacements needed every 2–5 years. Key signs of wear include unusual noises, reduced efficiency, or visible damage. Predictive maintenance tools like vibration analysis or thermal imaging can help identify issues early, ensuring timely replacements and avoiding unplanned downtime.

Are these modules compatible with all heavy industry equipment? Most modules are designed for broad compatibility with common heavy machinery brands and models. However, compatibility depends on specifications like load capacity, dimensions, and operational requirements. Manufacturers often provide customization services to tailor modules to unique machinery needs. Always consult technical documentation or supplier support to verify compatibility before purchasing.

What is the lead time for module delivery? Lead times vary based on complexity and customization. Standard modules typically ship within 2–4 weeks, while customized solutions may take 6–8 weeks. Suppliers with local warehouses or partnerships may offer expedited shipping for urgent orders. Planning ahead and maintaining an inventory of critical spares can mitigate delays. Many providers also offer emergency support for rapid replacements during unexpected breakdowns.

(Steel Industrial Spare Parts Heavy Industry Equipment Great System for Module)

REQUEST A QUOTE

RELATED PRODUCTS

Undercarriage Parts Crawler Spare Parts E70b Track Down Roller Track Roller Track Rollers Komatsu Pc10 Pc20 Pc27 Pc30-7 Pc35 Pc5

High quality Dongfeng heavy truck spare parts Cumins engine ISDE air compressor C5566135 air pump

High Top Wheeled New Komatsu PC80 Mini Spare Parts Forestry Used Excavator Mini

Underground Jumbo Drilling Rig Spare Parts For atlas copco /san/dvik Mining Machinery

Whole genuine sany heavy equipment and machinery spare parts sany crane spare parts