PRODUCT PARAMETERS

Description

Introduction of Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth

Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth refers to components that are specially designed and manufactured to replace or repair heavy machinery and equipment according to specific customer needs and specifications. These spare parts can be of any non-standard size, shape or function and are designed to meet the unique requirements of a specific application.

Advantages and features of Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth

Precise fit: Precisely matched spare parts for specific models or aging heavy machinery to ensure proper operation.

Extended life: High-quality materials and excellent artistry help to extend the life of machinery and equipment.

Cost-effective: Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth can significantly reduce costs compared to purchasing a completely new machine.

Rapid Response: The ability to respond quickly to customer needs shortens lead times and reduces downtime.

Innovative design: Using the latest technology and materials science to provide customers with optimized design solutions that improve efficiency and performance.

(Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth)

Specification of Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth

The Requirements of Building And Construction Hefty Machinery Spare Components Devices Pail Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Container Tooth fulfills high-performance requirements for heavy-duty excavation and earthmoving tasks. These parts are made from top-quality alloy steel. The product ensures sturdiness and resistance to abrasion. This makes them appropriate for severe working environments like mining, quarrying, and construction. The design focuses on longevity. It lowers wear during extreme operations. The teeth include a precision-engineered form. This enhances penetration right into hard products. It additionally improves excavating performance.

The HD-55 Dy130 Tl Container Tooth works with multiple equipment versions. It fits loaders, excavators, and bulldozers from major brand names. The dimensions are standard. This allows very easy substitute without changing existing devices. Each tooth goes through heat therapy. This process boosts hardness. It likewise prolongs life span. The ripper tooth layout consists of enhanced sides. These prevent early fracturing under heavy lots.

Setup is uncomplicated. The teeth connect firmly to adapter systems. This lessens downtime during maintenance. The surface is treated with anti-corrosion coatings. These protect against corrosion and chemical damages. The teeth preserve intensity longer. This decreases the requirement for frequent replacements. Operators gain from constant performance. Makers experience much less stress during operation.

The 208-939-3210Hd-55 model is developed for high-impact applications. It handles rough surface and thick soil efficiently. The structure disperses stress and anxiety equally. This stops local wear. The teeth are checked under severe conditions. They fulfill sector standards for strength and reliability.

These bucket teeth are offered in bulk or individual orders. Custom-made sizing alternatives exist for specialized machinery. The product comes with a guarantee. This covers production problems. Providers supply technological assistance for installment inquiries. Distribution timelines are flexible. Worldwide delivery choices come.

For prices information or certain requirements, speak to the distributor straight. Provide machinery model numbers for accurate compatibility checks. Supply availability differs by area. Verify preparations prior to putting orders. Replacement guidelines are included with each purchase. Comply with these to make the most of item life expectancy.

(Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth)

Applications of Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth

Building hefty equipment extra parts like bucket teeth and ripper teeth play a key duty in maintaining tools running efficiently. The 208-939-3210Hd-55 Dy130 Tl Pail Tooth is developed for usage with excavators, loaders, and excavators. These parts manage laborious like excavating, scraping, and breaking tough materials. They affix to containers and rippers, improving effectiveness in earthmoving and mining jobs.

Bucket teeth are crucial for excavating right into soil, rocks, and debris. The Dy130 Tl design is made from high-strength steel. This makes it resistant to wear and effect. It functions well in rough conditions like quarries or demolition sites. The ripper tooth helps break up compressed ground or asphalt. This minimizes strain on the machinery. Operators can finish work much faster with much less gas use.

Utilizing the ideal extra parts cuts downtime. Worn-out teeth cause delays. Changing them quickly maintains projects on time. The HD-55 style makes sure a protected fit. This avoids loosening during procedure. Compatibility with significant equipment brands makes these components versatile. They suit Cat, Komatsu, Hitachi, and others.

Mining and construction markets rely on long lasting teeth. They deal with hefty loads without fracturing. Regular maintenance checks are essential. Inspect teeth for wear or damages. Change them prior to they fail. This avoids pricey repair work to the bucket or ripper.

The 208-939-3210Hd-55 Dy130 Tl Pail Tooth is cost-effective. Premium materials expand its life expectancy. This saves money with time. Stocking these components minimizes equipment idle time. Customers need to confirm compatibility with their machinery. Correct installation makes certain peak performance.

These components are made use of in roadway construction, land clearing up, and material handling. They improve accuracy in digging trenches or rating surface areas. Operators notice much better control and minimized vibration. This lowers exhaustion throughout long shifts.

Vendors offer modification for certain needs. Firmness levels or dimensions can be changed. Constantly source parts from trusted makers. This guarantees they satisfy industry requirements. Reputable efficiency under hefty use is crucial.

The 208-939-3210Hd-55 Dy130 Tl Bucket Tooth is extensively offered. Ordering in bulk makes certain jobs stay on track. Technical support helps with installment or troubleshooting. Proper care makes best use of the worth of these components.

Company Introduction

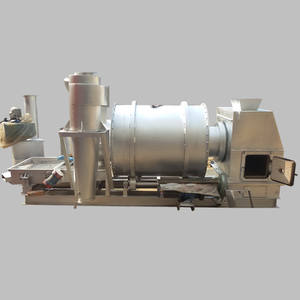

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth

What materials are used in the 208-939-3210Hd-55 Dy130 Tl bucket teeth? The teeth are made from high-quality alloy steel. HD-55 grade steel is used. This material is tough. It resists wear. Heat treatment is applied. This improves hardness. The teeth handle heavy loads. They work in rough conditions like rock or hard soil.

How long do these bucket teeth last? Lifespan depends on use. Average use gives 200-500 hours. Hard materials like rock reduce this. Softer soil extends it. Proper installation matters. Regular checks help. Replace teeth when worn down by 30-40%. This prevents damage to the bucket.

Are these teeth compatible with specific machinery models? Yes. They fit DY130, TL-series loaders. They match Hitachi, Volvo, Caterpillar buckets. Check machine manuals first. Match part numbers. Contact suppliers for exact fit. Wrong sizes cause poor performance.

How do I maintain bucket teeth? Clean them after use. Remove dirt and debris. Check for cracks daily. Tighten loose bolts. Lubricate pins. Avoid overloading the bucket. Rotate teeth if possible. Store spare parts in dry places. This stops rust.

Where can I buy genuine 208-939-3210Hd-55 Dy130 Tl bucket teeth? Buy from authorized dealers. Check supplier certifications. Avoid cheap copies. Fake parts wear fast. Contact trusted construction parts stores. Call the manufacturer directly. Verify product codes. Ask for warranty details.

(Construction Heavy Machinery Spare Parts Equipment Bucket Teeth Ripper Tooth 208-939-3210Hd-55 Dy130 Tl Bucket Tooth)

REQUEST A QUOTE

RELATED PRODUCTS

Heavy Equipment spare parts For Hyundai 210 290 Excavator Rock Bucket 0.52M3

High quality certified construction machinery spare parts with OEM number 129566 guaranteed affordable

Excavator spare parts Fuel Filter Element For 13058098 Air Filter heavy Duty Truck Oil Filters

Heavy Truck and Tire Remover Spare Parts Car Bus Wheel Balancer for

21Q9-32180 Excavator ORIGINAL Mcu Spare Parts Construction Machinery Parts For Hyundai MCU R330LC-9S hyundai excavator korea