Shipping hefty machinery is a complicated process that requires careful preparation, technical know-how, and adherence to safety protocols. As a mechanical designer, ensuring the risk-free transportation of heavy devices– whether across boundaries or locally– is crucial to stop damage, minimizing downtime, and minimizing economic dangers. Below are necessary tips to make certain the safe and secure and efficient shipping of heavy machinery.

(Essential Tips for Shipping Heavy Machinery Safely)

** 1. Conduct a Pre-Shipment Inspection **.

Thoroughly inspect the machinery before disassembly or product packaging. Check for loosened parts, hydraulic leaks, or structural vulnerabilities. Document the devices’s problem with pictures and notes to establish a baseline for liability. Test all systems to guarantee they are functional, as malfunctions found post-shipment could be misattributed to transit damages.

** 2. Take Apart and Safeguard Components **.

Minimize delivery dangers by dismantling bulky machinery right into convenient parts. Eliminate fragile components like sensing units, control panels, or protruding parts that might snap during transit. Label each part and pack them separately utilizing anti-static products, foam, or customized pet crates. Seal openings to prevent dirt, dampness, or debris access.

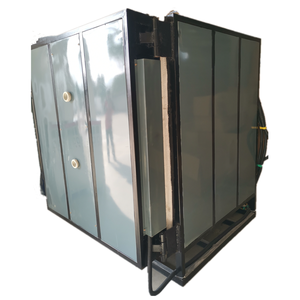

** 3. Use Custom-made Crating and Packaging **.

Typical product packaging is insufficient for hefty equipment. Go with enhanced steel or wooden cages designed to bear the devices’s weight and dimensions. Integrate shock-absorbing products such as high-density foam or air bags. For irregularly designed things, usage bespoke bracing systems to debilitate the lots. Make certain crates are weatherproofed with water resistant covers or desiccants to combat moisture.

** 4. Guarantee Compliance with Laws **.

Comply with international and local delivery laws, including weight restrictions, unsafe product guidelines, and safety standards. Confirm that the equipment meets the location nation’s import requirements, such as accreditations or emissions norms. Properly proclaim materials in shipping papers to prevent custom-mades hold-ups.

** 5. Select the Appropriate Transportation Setting **.

Pick the transportation method based upon equipment dimension, seriousness, and spending plan. Sea products fits extra-large, non-urgent shipments, while air freight is perfect for time-sensitive consignments. For land transport, usage low-loader trailers or flatbeds with the ability to take care of hefty tons. Always validate course restrictions, such as bridge weight restrictions or tunnel clearances.

** 6. Secure the Load Efficiently **.

Inappropriate tons securing is a leading root cause of transportation damages. Usage sturdy chains, ratchet bands, or spin locks to support equipment to the transportation car. Distribute weight evenly to prevent changing, which can undercut the service provider. For high tools, employ anti-tip devices and position the center of gravity as reduced as feasible.

** 7. Buy Comprehensive Insurance Policy **.

Even with precautions, crashes can occur. Acquisition all-risk insurance coverage to cover damages, burglary, or hold-ups. Review policy exclusions, such as acts of battle or improper packaging, and ensure the insurance coverage matches the equipment’s value. Keep inspection documents and packaging evidence to streamline claims.

** 8. Label and Document Clearly **.

Mark crates with taking care of instructions (e.g., “Fragile,” “This Side Up”) using resilient, weather-resistant labels. Consist of the gross weight, measurements, and center of gravity signs. Prepare exact delivery files, consisting of business invoices, packing listings, and certifications of origin, to speed up custom-mades clearance.

** 9. Partner with Experienced Logistics Providers **.

Collaborate with freight forwarders or service providers concentrating on hefty equipment. Validate their experience in dealing with large freight, conformity monitoring, and path optimization. Experienced partners can browse licenses, port handling, and last-mile shipment obstacles more efficiently.

** 10. Screen Transportation Conditions **.

Install IoT sensors or general practitioner trackers to keep an eye on real-time location, temperature, humidity, and vibrations. This data helps determine risky conditions, such as too much shocks, and enables proactive interventions. For sea products, confirm that the vessel has adequate securing factors and prevents harsh climate paths.

** 11. Plan for Unloading and Reassembly **.

Coordinate with the recipient to ensure dumping devices (e.g., cranes, forklifts) and skilled workers are readily available onsite. Supply reassembly handbooks or onsite technological support to recover equipment functionality quickly.

(Essential Tips for Shipping Heavy Machinery Safely)

Finally, shipping hefty machinery securely needs a blend of engineering precision, governing knowledge, and logistical insight. By focusing on robust product packaging, compliance, and specialist partnerships, mechanical designers can mitigate risks and make sure equipment arrives in optimal condition. These techniques not only shield properties however likewise support job timelines and operational integrity in international sectors.