PRODUCT PARAMETERS

Description

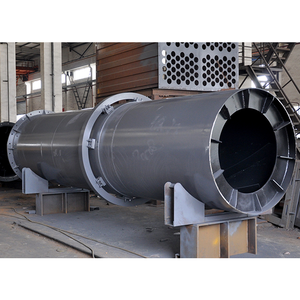

Introduction to New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components)

Specifications of New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

The New Multifunctional Rotary Drum Clothes Dryer Electric Heated is a versatile commercial service designed for efficient drying out applications in both the food and construction fields. It incorporates innovative core motor modern technology and a programmable reasoning controller (PLC) for accuracy, reliability, and automation. The clothes dryer uses an electric heater, ensuring consistent heat circulation and energy performance while getting rid of the need for fossil fuels, making it environment-friendly.

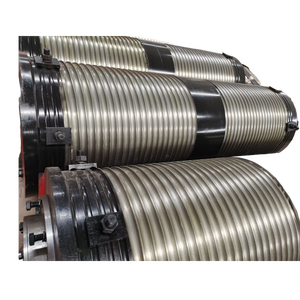

Built with a long lasting stainless steel drum (offered in food-grade 304/316L for food handling or sturdy carbon steel for building products), the rotating drum actions 2.5 meters in size and 8 meters in size, providing a capability of 500– 2,000 kg per set depending on material thickness. The drum rotates at a flexible speed of 3– 10 RPM using a high-torque, energy-efficient core electric motor (15– 30 kW power rating), crafted for continual procedure with very little maintenance.

Temperature level control ranges from 50 ° C to 300 ° C, flexible through the PLC interface to suit delicate food (natural herbs, grains) or robust building products (sand, accumulations). The PLC system includes a straightforward touchscreen for programs drying out cycles, keeping track of real-time data (temperature, humidity, turning rate), and saving personalized accounts. Safety mechanisms include emergency situation quit switches, overload protection, automatic closure for temperature level discrepancies, and alarm systems.

Protected walls minimize warmth loss, improving power efficiency by as much as 30% compared to standard dryers. Small dimensions (9m x 3m x 3.5 m) and a modular style facilitate setup in varied facilities. Additional features include easy-access assessment hatches, quick-release cleansing devices, and compatibility with IoT for remote surveillance. Created for toughness and conformity with industry security requirements, this dryer guarantees optimum efficiency, minimized downtime, and versatility throughout markets needing exact, high-capacity drying out solutions.

(New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components)

Applications of New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

The brand-new multifunctional rotating drum clothes dryer with electrical heating is an innovative service made to satisfy the varied drying demands of both the food and construction industries. Furnished with a high-performance core motor and progressed PLC (Programmable Reasoning Controller) parts, this dryer guarantees accuracy, effectiveness, and versatility across various applications. Its electrical heating unit removes the need for typical fuel-based techniques, making it eco-friendly and cost-efficient while preserving consistent temperature level control for ideal results.

In the food market, this rotating drum dryer master handling disposable goods such as fruits, veggies, natural herbs, spices, and grains. The electric home heating device provides mild, consistent warmth circulation, preserving nutritional worth, taste, and appearance while prolonging life span. The PLC system enables drivers to program specific drying cycles, changing specifications like temperature, airflow, and rotation speed to fit various items. For example, fragile natural herbs need low-temperature drying to preserve essential oils, while grains might require higher heat for reliable dampness removal. The food-grade stainless steel construction makes certain health compliance, and the closed-loop style stops contamination.

For the construction market, the dryer is optimal for processing resources like sand, cement, clay, and mineral accumulations. It successfully lowers moisture material wholesale materials, boosting their use in concrete production, smudging, or brick manufacturing. The durable core motor supplies high torque, making it possible for continual operation despite heavy, unpleasant tons. The PLC automates drying cycles, maximizing energy usage and decreasing human error. It also keeps an eye on real-time data, such as humidity degrees and drum speed, to keep product consistency. In addition, the clothes dryer can manage byproducts like industrial sludge or recycled construction waste, transforming them into multiple-use products.

Key features include the durable motor for long-term dependability, PLC-driven automation for precision, and modular styles for very easy scalability. The electrical heating system decreases carbon exhausts and operational costs contrasted to gas or diesel options. Whether drying food ingredients or building products, this multifunctional rotating drum dryer offers a versatile, lasting, and user-friendly remedy, satisfying the developing demands of modern-day markets.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components

**What industries is the New Multifunctional Rotary Drum Dryer designed for?**

This dryer is engineered for both food and construction industries. In food processing, it handles herbs, grains, spices, and dehydrated fruits, ensuring compliance with hygiene standards. For construction, it dries sand, minerals, aggregates, and cement raw materials. Its versatile design adapts to varying material types and moisture levels, making it ideal for dual-sector use.

**How does the electric heating system improve efficiency?**

The electric heating system replaces traditional fuel-based methods, offering cleaner operation, precise temperature control, and reduced carbon emissions. It ensures uniform heat distribution within the drum, minimizing energy waste. This results in faster drying cycles, lower operational costs, and consistent output quality, critical for temperature-sensitive food products and construction materials requiring specific moisture content.

**What role does the PLC component play in this dryer?**

The Programmable Logic Controller (PLC) automates drying cycles, enabling users to preset parameters like temperature, rotation speed, and duration. It monitors real-time data, adjusts settings for optimal performance, and reduces manual intervention. The PLC enhances precision, repeatability, and safety, while its user-friendly interface allows operators to track progress and troubleshoot issues efficiently.

**Is the dryer safe for food-grade applications?**

Yes. The drum and components contacting food materials are made of stainless steel, which is non-toxic, corrosion-resistant, and easy to sanitize. The system complies with food safety standards (e.g., FDA, HACCP), ensuring no contamination. The closed-loop electric heating prevents exposure to combustion byproducts, making it ideal for food processing.

**What maintenance does the dryer require?**

Routine maintenance includes inspecting the core motor for wear, cleaning the drum to prevent residue buildup, and updating PLC software. The motor’s durable design reduces breakdowns, while the PLC’s diagnostic alerts flag potential issues early. Annual professional servicing is recommended to check electrical components and seals. Maintenance is minimal compared to conventional dryers, ensuring long-term reliability.

(New Multifunctional Rotary Drum Dryer Electric Heated for Food and Construction Industries with Core Motor and PLC Components)

REQUEST A QUOTE

RELATED PRODUCTS

Single rotary drum dryer for biomass rice husk sa and secador rotary dryer pellet for phosphates and sand dryer spare parts buck

Professional Rotary Dryer 500Kg / Rotary Drum Dryer / Double Cone Dryer

High quality Dryer parts Electric Dryer Heating Element 3387747 Heating parts 3387747

Industrial silica sand Browncoal wood sawdust rotary drum dryer machine, three cylinders drum dryer

HG series double rotary drum dryer industrial food